/Home products/Components For Household Appliances

COMPONENTS FOR HOUSEHOLD APPLIANCES

Marcegaglia has located in Praszka part of its production of wire-on-tube and louvred condensers (static or ventilated), spiral condensers and no-frost modules to meet the demands of the refrigeration industry. The components are designed and manufactured along with the customer, to ensure their optimal fitting in the final equipment in terms of performance, costs and energy consumption; they can be customized on request and supplied with all sorts of finishings.

Marcegaglia supplies the major production districts through its production network worldwide in the sector of components for household appliances which includes, in addition to the Praszka plant, located in southern Poland, the Garuva plant, in the state of Santa Catarina in Brazil and the IMAT plant in Fontanafredda (Pordenone) in Italy.

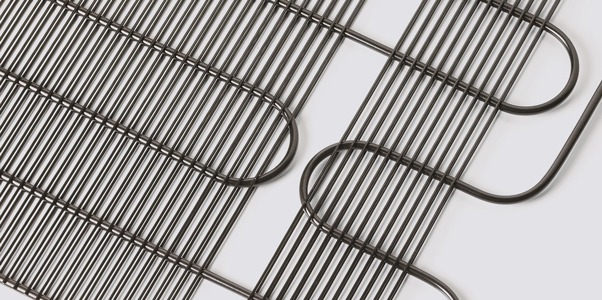

Serpentine with electric welded wires on both sides

FEATURES

- Steel tube UNI EN 10139-DC04, external Ø 4.76 x 0.7 mm

- Serpentine pitch 50 – 25 mm

- Wire width: 350 mm – 1,000 mm

- Wire height: 300 – 1,450 mm

- Cold-drawn steel wires 3CD 5 UNI 5598-71, external Ø 1.4 mm, wire minimum pitch 5 mm

- Black cataphoresis paint

- Cleanness and internal humidity according to DIN 8964

- Saline mist as per ASTM 8117/ISO 9227 > 48 h

ON DEMAND

- Single or double entry dryer

- Charging tube

- 100%-tested welds • Fixation brackets

FIXING SYSTEM On request, welding of fixing brackets, made of steel FeP01 UNI 5961-67, available for different kind of chimneys (height from 0 to 25 mm).

Steel sheets with a central louvre and canal on both sides, welded together closing the serpentine inside the canals. Tubes free from welds.

FEATURES

- Steel tube UNI EN 10139-DC04, external Ø 4.76 x 0.7 mm

- Serpentine pitch 60 – 32.5 mm

- Width 342 – 780 mm Height: 240 – 1,456 mm

- Steel plate UNI EN 10139-DC01

- Steel sheets thickness 0.3-0.4 mm

- Black cataphoresis paint

- Cleanness and internal humidity according to DIN 8964

- Saline mist as per ASTM 8117/ISO 9227 > 48 h

ON DEMAND

- Single or double entry dryer

- Charging tub

- 100%-tested welds

FIXING SYSTEM

Different solutions of parallel or inclined shoulders. Availability of different kind of holes on the condensers shoulders.

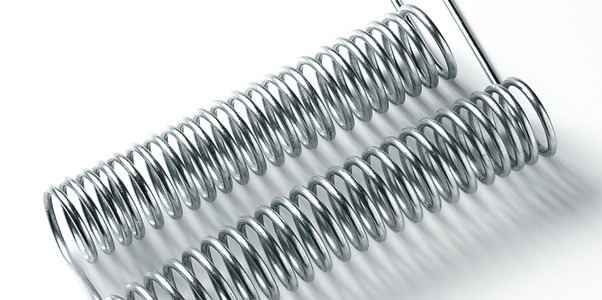

The spiral condensers have been designed to be mounted in restricted areas, under ventilation. Tubes free from welds.

FEATURES

Steel tube UNI EN 10139-DC04, hot-dip galvanized, external Ø 4.76 x 0.7 mm

- Spiral pitch 7 mm – 20 mm

- Specific internal diameter of the spiral upon request

Spirals centres distance, upon request

- Spiral length 80 mm – 300 mm

- Cleanness and internal humidity according to DIN 8964 • Saline mist as per ASTM 8117/ISO 9227 > 48 h

ON DEMAND

- Single or double entry dryer

- Charging tub

- 100%-tested welds

ON DEMAND

Specific end bending

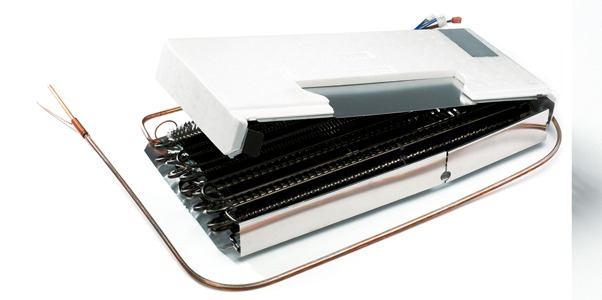

Design and manufacture of no-frost modules, supplied as full kit on the basis of the white-good specifics.

FEATURES

Consisting of:

- Finned evaporator

- Fixing brackets

- Exchanger tube with capillary

- Defrosting heater

- Aluminum back plate

- Aluminum front plate

- EPS parts

- NTC sensors

- Thermal fuse/disjunction

- Wiring, fixing, screws, rivet